-

58%

Respondents consider Configuration Management as a core function of PLM

-

45%

Efficiency Increased for data collaborations among product development, production & marketing

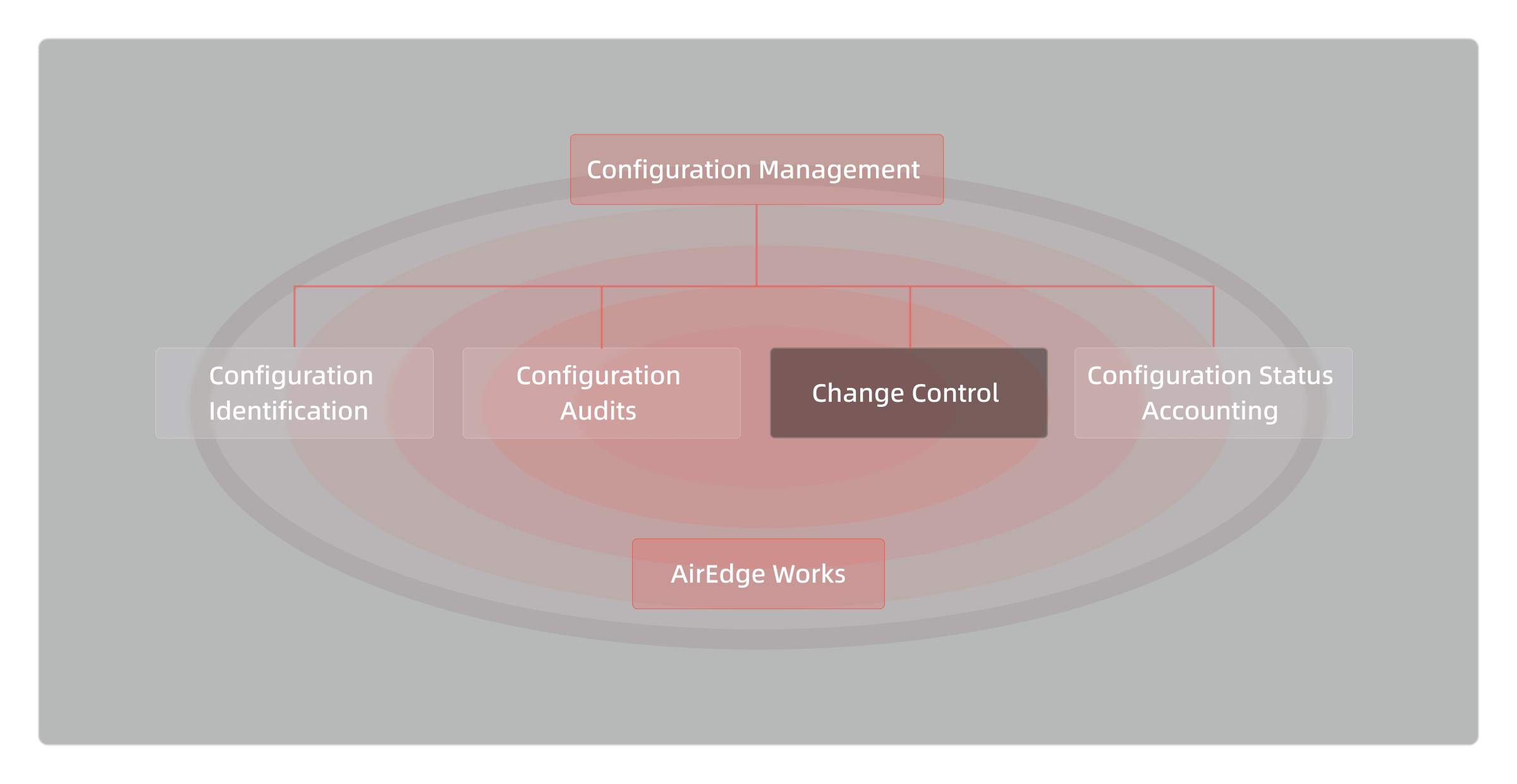

Standardized, Compliance driven and Change Controlled Configuration Management

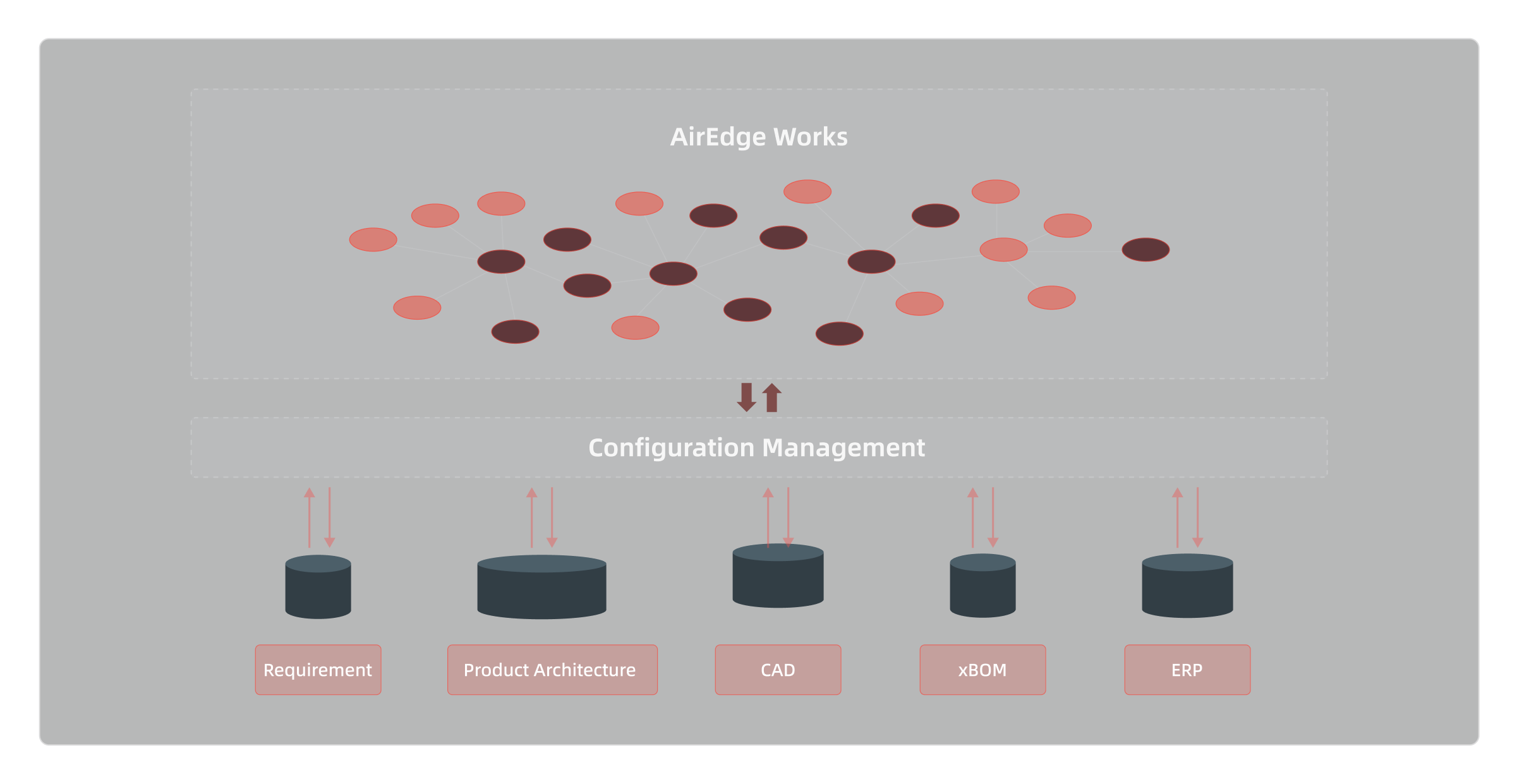

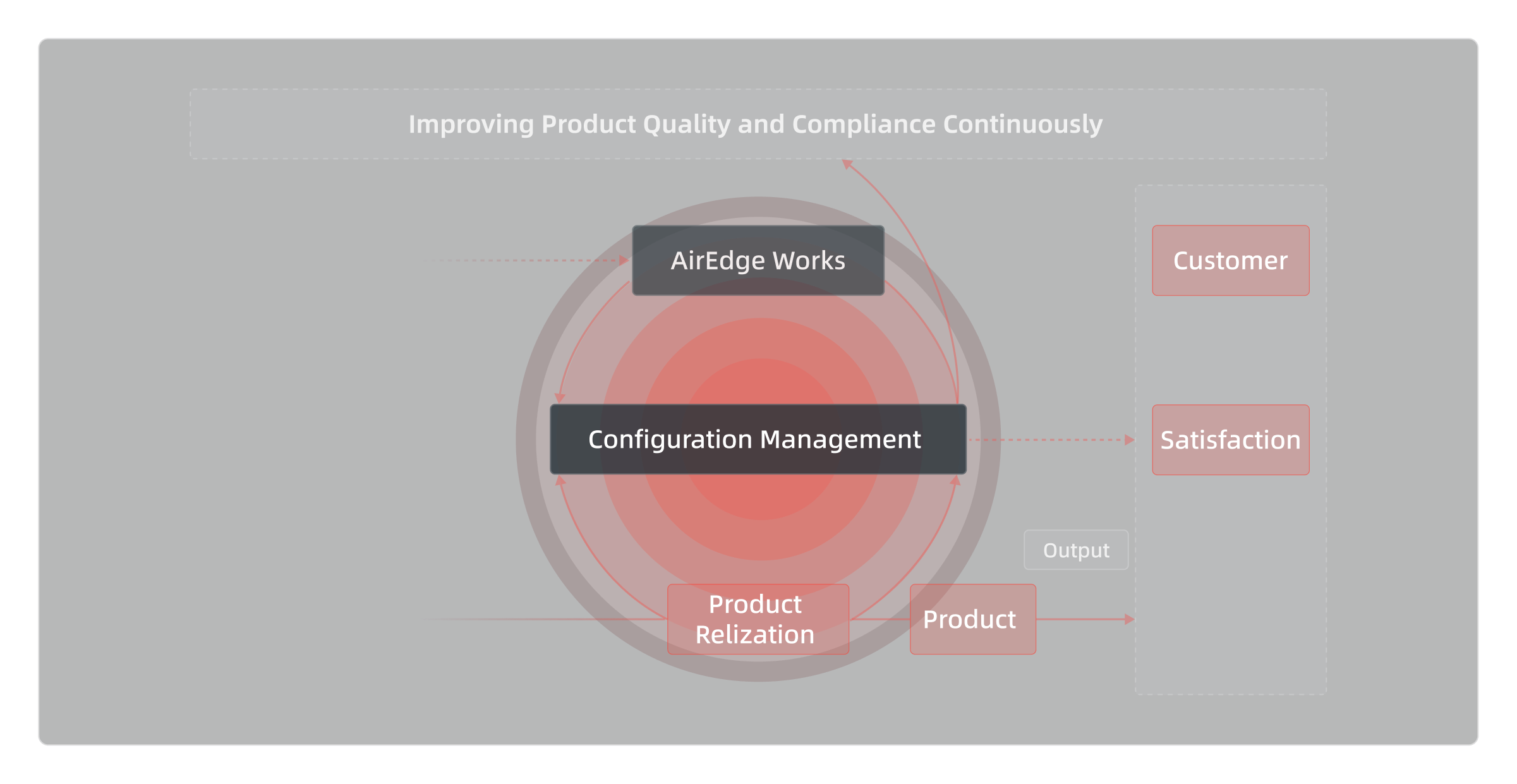

Configuration management offers standardized product data and improved regulatory compliance, enhancing quality, reducing costs, and boosting competitiveness. It also ensures effective tracking of design and production changes, improves data consistency, and speeds up time-to-market.

Business Challenges

-

Rigorous Regulatory Requirements & Standards

The aerospace industry faces strict regulations and standards, necessitating that configuration management adapts to these evolving requirements.

-

Product Data Inconsistencies & Traceability Issues

Ensuring accuracy, consistency, security, accessibility, and traceability of configuration-managed data across different systems throughout its lifecycle is challenging.

-

Difficulties in Integration with Existing Systems

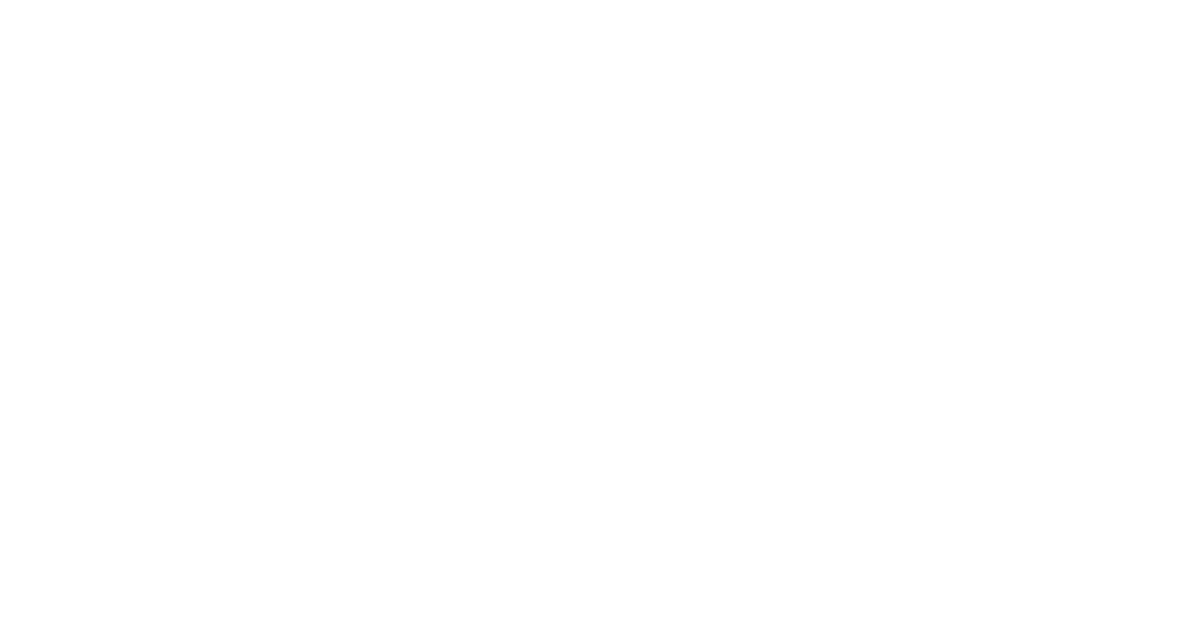

Implementing a PLM-based configuration management tool requires integrating with existing ERP, CAD, and other software to ensure real-time data synchronization and control.

Typical Solutions

-

Standardized Product Data

Configuration management ensures consistency and accuracy of product information. With AirEdge Works, all related data, including design specifications, process steps, and production requirements, are maintained and managed throughout the product lifecycle.

-

Enhanced Quality Control and Compliance

By monitoring changes in product configuration, companies can better control product quality, identify potential issues early, and take preventive measures. It also ensures adherence to relevant regulations by tracking configuration changes and ensuring all designs meet required standards.

-

Support for Change Management

Changes are inevitable in product development and production. Configuration management tracks these changes, ensuring all stakeholders have access to the latest product information.

-

Improved Customer Satisfaction

Ensuring product consistency and quality through configuration management enhances final product performance and customer satisfaction. It also speeds up the design-to-production process, enabling companies to respond more quickly to market changes and customer needs.

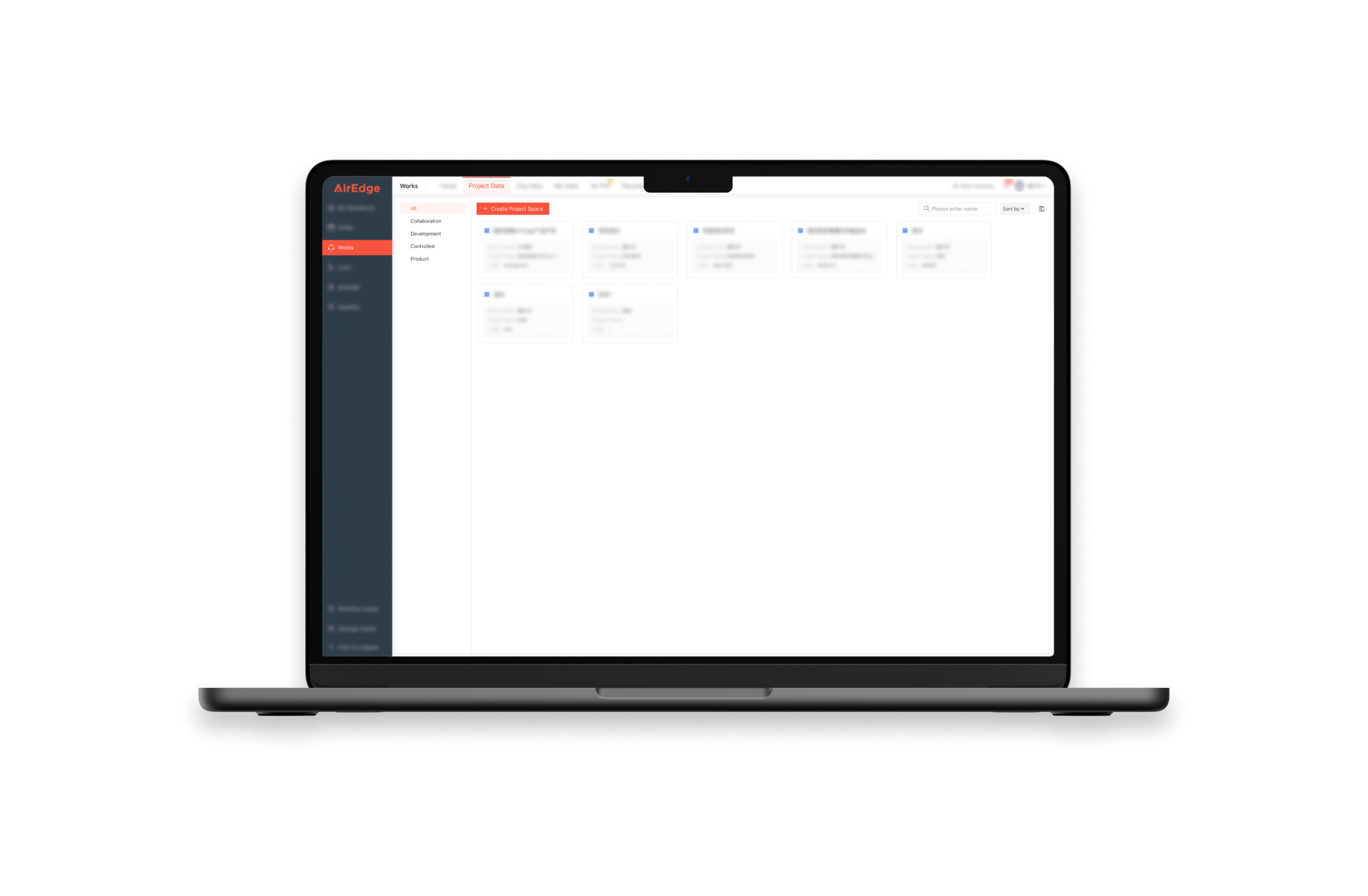

AirEdge Functional Modules

-

Configuration Management

-

Requirement Engineering

-

Airborne Software & Hardware Development

-

Multidimensional Project Management

-

Product Data Management

-

Change Management

Compliance Driven Development Powered by AirEdge

Incorporate and facilitate compliance throughout the lifecycle process pilot